- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-431-81881745

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

Company News

Current position :Home > News > Industry News

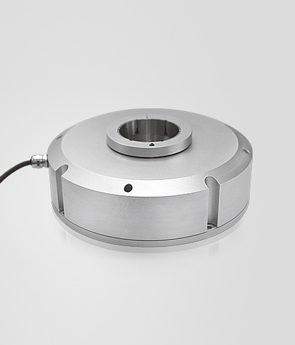

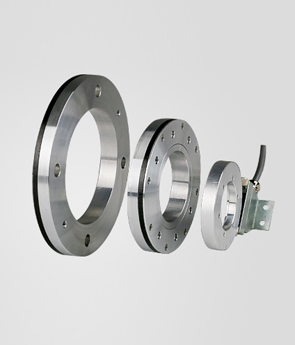

Encoder technologies!

Changchun Rongde Optics Co.,Ltd. Release time:2015/4/9 Browse:1214First of all,it is conductive. A series of circumferential copper tracks etched onto a PCB is used to encode the information. Contact brushes sense the conductive areas. This form of encoder is now rarely seen except as a user input in digital multimeters.Secondly, it is optical. This uses a light shining onto a photodiode through slits in a metal or glass disc. Reflective versions also exist. This is one of the most common technologies. Optical encoders are very sensitive to dust.Thirdly, it is on Axis Magnetic. This technology typically uses a specially magnetized 2 pole neodymium magnet the same size as the motor shaft that typically requires a custom motor shaft be used. The accuracy is very bad and does not allow many resolution options. This technology does not typically offer UVW or Z pulse outputs. Due to the 2 pole magnet there is lots of jitter on the output due to the internal interpolation.Last but not least, it is off Axis Magnetic. This technology typically employs the use of rubber bonded ferrite magnets attached to a metal hub. This offers flexibility in design and low cost for custom applications. Due to the flexibility in many off axis encoder chips they can be programmed to accept any number of pole widths so the chip can be placed in any position required for the application. Magnetic encoders operate in harsh environments where optical encoders would fail to work.

Previous:the working principle of rotary encoder

Previous:the working principle of rotary encoder Next:LINEAR DISPLACEMENT SENSOR

Next:LINEAR DISPLACEMENT SENSOR

Products

Products