- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-431-81881745

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

Company News

Current position :Home > News > Industry News

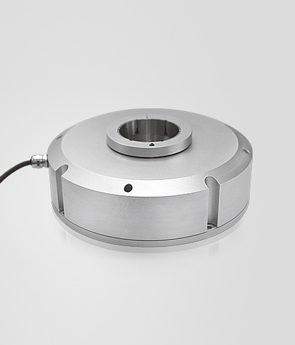

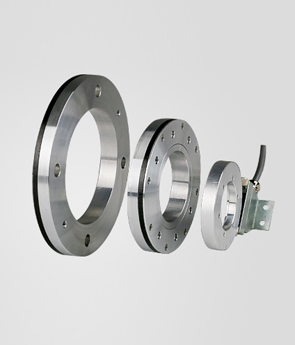

Absolute rotary encoder for elevator control!

Changchun Rongde Optics Co.,Ltd. Release time:2018/6/29 Browse:1089When the user selects an elevator, the advantages of compact structure, high power density, no maintenance and high power efficiency are playing an important role. For passengers to feel more comfortable and constantly improve the quality, we need innovative and efficient drive systems, including the motor and control system. The technical basis of this innovative system is to provide a position value feedback system so that in the control unit the actual shaft speed of the motor can be determined and the motor coils commutated at the correct phase. Especially in elevator applications, the advantages of absolute rotary encoders are even more pronounced. Because this type of rotary encoder has a high resolution and uses a pure serial transmission protocol (without additional incremental signals), this directly relates to the passenger's experience with the elevator ride. In addition, the most significant advantage of absolute encoders for elevator users is that they can provide more features in the background.

The specified position value (such as zero) transmitted through the bidirectional serial interface simplifies the control unit operation and enables the control unit to efficiently provide a commutation signal for the motor magnetic field at the correct phase to ensure optimal torque.

Another advantage of the bidirectional interface is the communication between the motor and the control unit. On the one hand it is able to transmit position values, on the other hand it can also transmit parameters related to specific encoders and motors. This information is read from the storage area of the rotary encoder to the control unit during the system startup phase and in the system configuration. The factory can use this function to pre-load the relevant parameters, shorten the debugging time in the first use and avoid the possibility of manually inputting parameters to the drive system.

Not only that, but this interface also has monitoring capabilities that make the elevator more reliable. Advanced rotary encoder electronic circuit design also provides signal processing capabilities for temperature sensors. In addition to the temperature sensor inside the encoder, this encoder allows the temperature sensor circuit board at the motor coil to be connected and temperature signal processed and the processed data transmitted to a higher level electronic circuit through the transmission protocol.

In addition, the diagnostic value of the effective digital form generated in the encoder electronic circuit is also transmitted through this interface to perform the functional redundancy judgment of the encoder. When the critical value is reached, necessary protective measures must be taken to avoid unplanned downtime and maintenance

The new rotary encoder, which uses pure serial transmission of data, is very resistant to electromagnetic interference because it uses noise-transmitting technology for data transmission with very high reliability. Since the scanning signal is subdivided within the rotary encoder, only one cable of 6-8 wires is sufficient for the connection, and it is no longer necessary to monitor the long cable voltage drop telemetry line.

The encoder with subdivision and bidirectional serial interface has rich functions and is an ideal choice for the control system of elevator motor.Its data transmission capabilities, such as transmission of absolute position values, high resolution, short cycle time for transmitting digital position values, and better connection technology enable it to improve control system performance. Its monitoring and diagnostic functions help users prevent Maintenance and regular maintenance.

Previous:Intelligent absolute encoder apply to the wind driven generator

Previous:Intelligent absolute encoder apply to the wind driven generator Next:Application of Photoelectric Sensors in Airport Logistics

Next:Application of Photoelectric Sensors in Airport Logistics

Products

Products