- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-431-81881745

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

Company News

Current position :Home > News > Industry News

Application of rotary encoder in metallurgical production line!

Changchun Rongde Optics Co.,Ltd. Release time:2018/11/9 Browse:1394The hot rolling production line is one of the important production lines in the metallurgical industry. Most of its mechanical devices are driven by AC variable speed motors, and the speed control mode is mainly based on frequency conversion speed regulation.

The hot rolling line generally consists of a slab library, a heating furnace, a rough rolling, a finishing rolling, a coiling and a transportation chain. As an important equipment for the rolling line, the flying shear system can be installed on the rolling line of the continuous rolling mill, shearing the head and tail of the rolling stock or cutting the rolling stock into a fixed length; using a flying shear is beneficial to The rolling steel production will be rapidly developed in the direction of high speed and continuous.

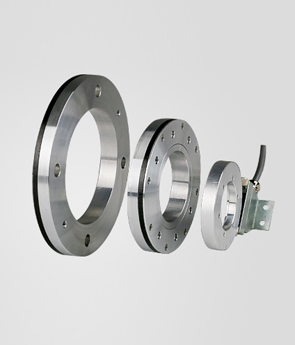

Therefore, it is one of the important means of rolling steel production development. Rolling mill theory: Rolling is a material that draws rolling stock between the rolls by the friction of the rotating rolls, and at the same time relies on the pressure applied by the rolls to cause the rolling parts to compress and deform between the two rolls or two or more rolls. processing methods. The main drive system of the rolling mill adopts a full digital speed control system. The speed controller contains a voltage loop, a current loop, and a speed loop. The speed loop feedback component uses an incremental encoder. The incremental heavy-duty large-sleeve rotary encoder and the speed control device have better application effects, stable speed control, fast speed response and high speed regulation precision. The lower pinch roller is configured to control the speed of the stick by configuring the encoder to synchronize the flying shear and the pinch rolling mill.

Previous:Application of rotary encoder in robotic arm of automation field

Previous:Application of rotary encoder in robotic arm of automation field Next:Rotary encoder application in the field of elevators

Next:Rotary encoder application in the field of elevators

Products

Products