- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-0431-81856009

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

Application of Encoder Products in Iron and Steel Smelting Industry!

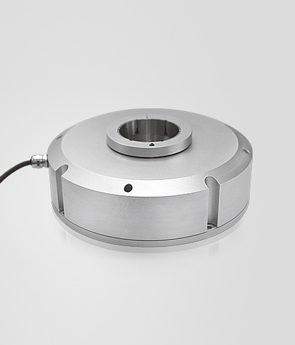

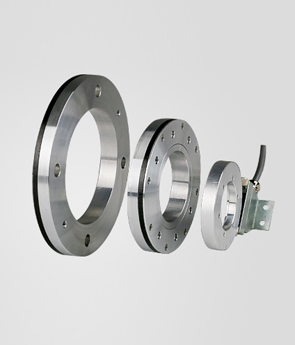

Changchun Rongde Optics Co.,Ltd. Release time:2018-06-30 Browse:935In the workshops of sintering, iron making, steel making and steel rolling of large steel groups, various cold rolling mills, hot rolling mills and driving equipment are equipped with encoder products. The most advanced absolute encoders are used on newly reconstructed large-scale driving equipment. Its precise measuring capability effectively meets the requirements of users to know the driving speed and position of driving equipment in a severe environment, minimizing the risk of using mechanical equipment, enabling the control personnel to know the position of the driving in a timely and accurate manner. Information and drive system operating speed information, effectively ensure the safe operation of the equipment, and provide a guarantee for safe production.

Steel plant driving equipment is an essential high-altitude mechanical equipment in the iron and steel smelting process. It is widely used, such as the blast furnace filled with molten iron in the mobile steel production workshop to the corresponding station, the timely delivery of the hot slab, the loading and unloading of the slab, heating furnace and on to cooperate to complete the furnace area of various maintenance lifting work, etc. In the production process of iron and steel smelting, it is based on management and safety requirements, each vehicle must operate safely, accurately and efficiently according to the systems. This requires the operator to have a good understanding of the operation of the drive system. The encoder is an automation product that is connected with the drive system. Through continuous detection, the corresponding information data is transmitted to the upper system. The choice of encoder products is very important.

Due to the heavy responsibility, it is very important for the encoder to ensure the accuracy of the measurement data. But there are not many products that can satisfy with harsh environmental requirements as steel mills actually. Iron and steel smelting workshops are complex and changeable, with many vibrations, high temperatures, dust, and even corrosive substances. The encoder product has a high level of dustproof and waterproof performance, and is designed with strong shock and vibration resistance according to the general requirements of heavy-duty environment, making it fully meet the needs of heavy-duty environments.

The product adopts aluminum or stainless steel shell, its sturdy and durable mechanical device, this is very important that the steelworks workshops are often kept at high temperature. The strong high-temperature resistance is enough to ensure the normal use of the product. It can also set the alarm function. Once the preset vibration intensity and temperature are exceeded, it is coded. The device will feedback the alarm signal to the user, which is worthwhile.

Previous:Draw wirw sensor note

Previous:Draw wirw sensor note Next:Absolute encoders for solar power tracking systems

Next:Absolute encoders for solar power tracking systems

Products

Products