- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-431-81881745

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

Company News

Current position :Home > News > Industry News

absolute value encoder of the 900t large tire trolley applications!

Changchun Rongde Optics Co.,Ltd. Release time:2018/8/7 Browse:1103

900t large tire trolley is specially designed to meet the construction of railway passenger dedicated lines. It is mainly used to transport large-tonnage concrete precast box girder. It can complete 20, 24, 32m double-line full-hole box girder from prefabricated yard to frame beam station in order to transport and work with the beam. With the increase of the number of dedicated lines and the high requirements for the quality of the project, the automation level of the control system of the bridge girder erection machine, the beam conveyor and other related equipment, as well as the stability, reliability and accuracy of the equipment operation are becoming more and more higher.

The electrical control system of the transporting girder vehicle adopts the CAN bus technology, and all electrical control is realized by the PLC relying on the field bus.

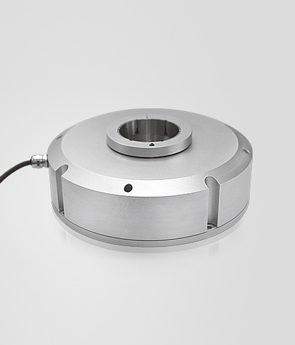

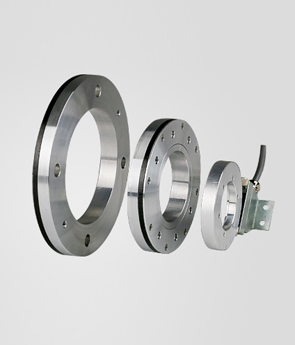

The system uses the CAN bus protocol absolute encoder, through practical test, the encoder CAN be adapted to field operation environment, stable operation, safe and reliable.

The beam truck is a multi-axis rubber-tyred walking machinery with multiple steering modes. The safe and reliable positioning of the beam transporter determines whether the bridging work can be completed safely, quickly and with high quality. Therefore, the steering control of the beam truck determines the operability, stability, safety and safety of the beam truck. accuracy.

The steering of the traditional beam truck is mechanically controlled, and the direction of the wheel and the amplitude of the swing are controlled by a tie rod. The mechanical tie rod control system has the disadvantages of serious tire wear and limited swing amplitude, so the construction efficiency is low, which affects the construction period.

The current automatic control system uses absolute encoders as feedback for steering angle and swing amplitude, relying on fieldbus control. The system successfully overcomes the problems existing in the control system of the tie rod, and has the outstanding advantages of fast, stable, high control precision, and can be controlled by different algorithms according to the site conditions, thus driving the leap in the performance of the beam truck and effectively improving the rack. The efficiency and quality of the bridge work.

Previous:Absolute value encoder used in ships, warships of successful cases

Previous:Absolute value encoder used in ships, warships of successful cases Next:Encoder in the lifting industry the application of synchronous rectification control

Next:Encoder in the lifting industry the application of synchronous rectification control

Products

Products