- Changchun Rongde Optics

- Co.,Ltd.

- Add:No.1666 Yaan Road,

- North Lake Development District,

- Changchun 130102,China

- Tel:86-431-81881745

- Fax:86-0431-85256892

- E-mail:rongdecui@roundss.net

- Skype:adacui_roundss

Company News

Current position :Home > News > Industry News

Absolute value encoder used in ships, warships of successful cases!

Changchun Rongde Optics Co.,Ltd. Release time:2018/8/13 Browse:1145The sensor products used by ships and warships all require high quality assurance. Because the application of the ship will face the harsh environment of high temperature, high humidity, high salt and high vibration, and ships and warships sail for several months, in the boundless sea, in the boundless sea, sensor product performance is directly related to the ship and personnel safety. Therefore, the marine products have certification requirements such as China Classification Society and British Lloyd Class Classification Society. If they are used on warships, they are the best of these products.

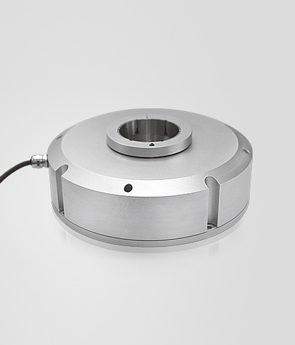

Case 1: Application case of pulley rope contraction

Problem: Large ships are docked and stopped. The ropes of fixed ships are directly placed by hand and motor. The ropes of large ships require many people to observe and release the ropes at different positions. The length of the rope out and the length of the back always repeat many times to be sure. It is always necessary to repeat the operation several times to determine, which results in a loss of manpower, material resources and time and energy.

Solution: Select multi-turn absolute value, 4-20mA analog signal output, install the encoder on the pulley of each rope, measure the length of the rope and do the program in the PLC, and feedback the rotation signal of the encoder. When the PLC is used to realize the retracting and retracting of the ropes, it usually needs only one person to complete, which saves time and effort and greatly improves the efficiency. The encoder turns manual operation to automated control for precise positioning. Low-industrial encoders for encoders used on ships are not possible. There are many factors to consider, such as corrosion, grounding, signal transmission and temperature on the sea. Generally, low-grade encoders are impossible.

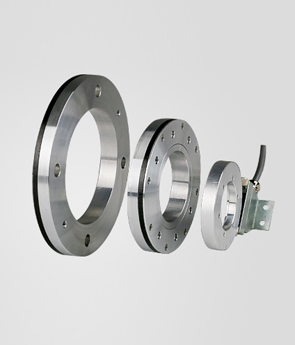

Case 2: Application of Synchronous Control of Drawstring Displacement Sensor on Cylinder

Problem: Large ship rudder blades and propellers are of large quality, up to several hundred tons, with rudder blades and propellers moving up and down vertically. The hydraulic system design relies solely on the natural connection of a hydraulic system to the four drives on the four corners of the trolley platform. Ascending cylinder, because the distance between the four cylinders and the hydraulic source is different, the pressure loss of the pipeline is different, and the speed of the four cylinders moving up and down is very different. Therefore, the rise and fall of the trolley platform is actually in a tilting situation. In sports, when it is serious, there will be obvious tilting, which will cause safety hazards.

Solution: It is necessary to use the rope displacement sensor and the multi-turn absolute encoder PLC with 4-20mA output to control the synchronization of the four hydraulic cylinders. It is difficult to achieve high-precision synchronization of multi-cylinders, especially in large loads and large When the load and the load distribution are uneven, the displacement sensor is used for real-time position feedback, and the proportional servo valve controls the cylinder flow in real time to realize the precise control of the cylinder displacement. The master-slave synchronization control strategy is used to realize four main jacking Synchronous movement of the cylinder.

Previous:Encoder apply to ZOYON-RTM

Previous:Encoder apply to ZOYON-RTM  Next: absolute value encoder of the 900t large tire trolley applications

Next: absolute value encoder of the 900t large tire trolley applications

Products

Products